We have a solution for you.

The number of electronic control modules on a vehicle continues to increase rapidly. Every vehicle line, from entry-level to high-end luxury, is exploding with new functionality, from driver assistance to infotainment. Modules firmware is becoming more complex to support these new functions. Vehicle features are expanding with multiple networks to support them. The supplier base is widening with more suppliers providing more control modules on more vehicles.

With an increased reliance on network communications, a module that is non-compliant with the network communication specification causes problems during vehicle network integration, manufacturing, and after sale support.

- As more suppliers are providing more modules, it is likely that the first time a module communicates with its peers is the first time it is placed on the vehicle network with modules from other suppliers. When a problem occurs it is difficult to determine which modules are causing the problem.

- During vehicle manufacturing, non-compliant modules create problems during end-of-line testing. Special test procedures to deal with the module can complicate test procedures and increase test time.

- Non-compliant diagnostic messaging causes problems during the development of after sale troubleshooting tool development, incorrect diagnosis, or failures during legislated emissions testing.

- Compliance testing is expensive and time consuming.

As a third party independent test activity, EnGenius provides several benefits to tier suppliers and vehicle OEMs.

- They provide a local resource to suppliers without a presence in the US or familiarity with OEM test requirements

- Provides independent confirmation of compliance with requirements.

- A highly automated test process provides rapid feedback from testing.

EnGenius provides outsourced module compliance testing in the following areas.

Physical Layer Compliance

Physical layer compliance includes (but is not limited to) testing for:

- Adherence to electrical specifications (capacitance, resistance, inductance, voltage levels, etc.).

- Edge timing, slew rate, waveform, etc.

- Data rates, bit timing, and encoding.

Protocol Compliance

The network messaging is checked against the requirements for:

- Correctly formed messages.

- Appropriate in-frame responses.

- Adherence to protocol timing.

- Transport layer compliance.

Module Specific Compliance

The module is put into the desired state by providing the appropriate network messaging and analog/digital signals. Network traffic is checked for:

- Periodic and event message timing.

- Supported messages (operational and diagnostic).

- Module response to messages.

- Message format: data checked for correct size, content, location, and transformation.

- Digital and analog I/O.

On-Vehicle Compliance

An on-vehicle compliance test monitors the vehicle networks via the J1962 connector. Network traffic that pertains to the module under examination is compared to module network interface specification. Conditions such as missing messages and incorrect timing or periodicity are flagged. Additional vehicle analog and digital signals can be included to further define the expected network operation.

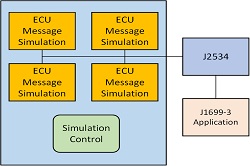

SAE J1699-3 Software Validation

The SAE J1699-3 Recommended Practice is used to verify that a vehicle supports a minimum subset of the diagnostic test services specified in SAE J1979 or ISO 15031-5. J1600-3 specifies the test sequence to run; the J1699-3 software executes the test sequence and is used to test a vehicle for compliance.

For the past 15 years, EnGenius has provided software validation of the J1699-3 Vehicle OBD II Compliance Test Cases open source software. The testing uses EnGeniusTEST to implement the defined test cases and report compliance with the SAE standard.

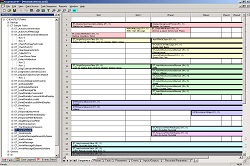

EnGeniusTEST

Unless other tools are specified by the customer, EnGenius uses EnGeniusTEST to perform protocol, module specific, and on-vehicle compliance testing.

The EnGeniusTEST platform, built on National Instruments TestStand®, provides a highly capable test development and execution platform that provides a powerful set of tools that can be applied to a broad range of test applications from control modules to telematics to infotainment.

Tests developed in EnGeniusTEST integrate network messages with analog and digital I/O and other data acquisition hardware to effectively and repeatably run test cases in a "black box" test environment achieving up to 90% reduction in test time over manual test case execution with the added benefit of automated data collection and results reporting.

Reduced test execution time allows multiple unattended back-to-back runs of the suite of test cases that can reveal failures that may not be captured in a single pass through the test suite.

When needed, EnGeniusTEST can integrate with external high-fidelity real-time simulations of sensors, actuators, and other items such as dynamic engine simulations to provide time critical stimulus and response to the module firmware.

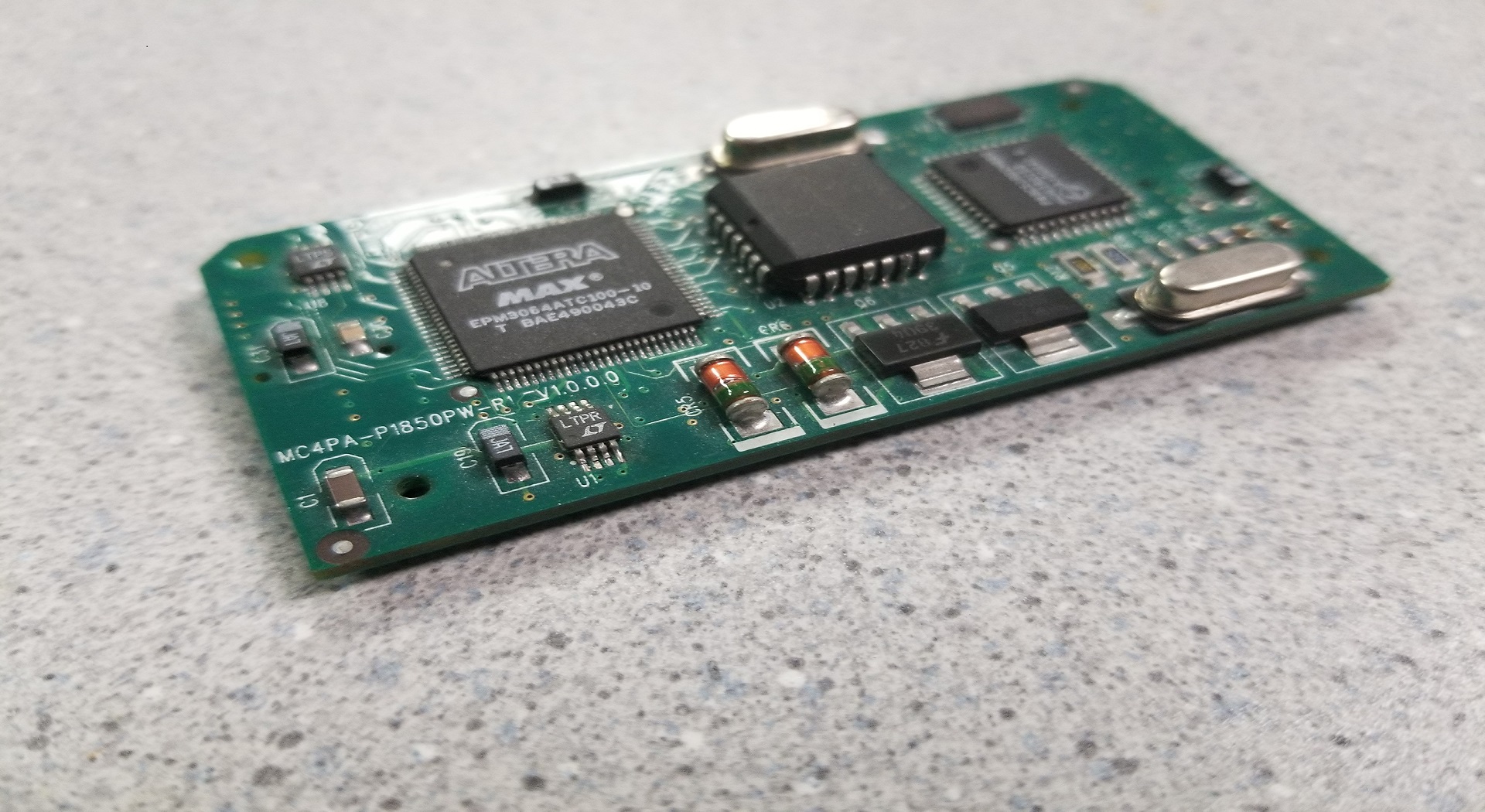

In addition to the EnGeniusTEST platform and the MultiCom family of multiplexed network interface adapters, EnGenius provides outsourced test case development, software validation, custom "pot boxes", and DV/PV/EOL test stations to support software development and validation testing.